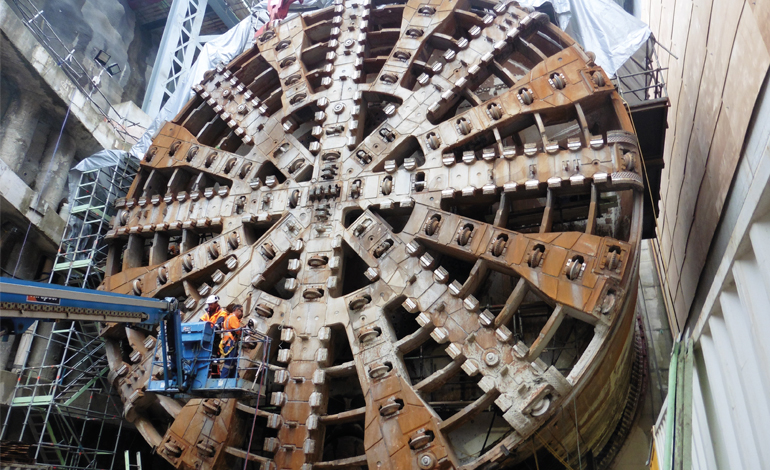

CHRIS WEBB says farewell to Alice, the tunnelling machine that chewed her way through 800,000 cubic metres of spoil under Auckland and laid more than 24,000 tunnel lining segments in her wake for the country’s biggest ever highway project, the $1.4 billion Waterview Connection.

ALICE, ONE OF THE world’s biggest tunnel boring machines (TBMs) ever built, has been reduced to her component parts ready to be shipped back to her German maker.

A significant chapter in our rich construction history is drawing to a close, with the dismantling and removal of ‘Alice’, the giant TBM used by the Well-Connected Alliance to drive twin 2.4 kilometre tunnels for the $1.4 billion Waterview Connection. This delicate and challenging operation, is scheduled to be completed this month (February) by Smith Crane and Construction (SCC).

Game changing

Jason Bourke, the company’s national crane hire manager, says construction of one of our longest and biggest ever road tunnels has been a “game changing” project for SCC.

“The New Zealand Transport Agency’s [NZTA] Waterview Connection project is the biggest job we have ever undertaken. For a South Island based company to have fought off companies from Australia and all over the world to secure the contract was very satisfying and shows we can tackle the heaviest work.”

Two of the country’s biggest cranes – SCC’s 600-tonne crawler and a 280-tonne mobile – took part in some of the heaviest lifts ever undertaken on a construction project here, including that of removing Alice’s 400 tonne main drive from the southern access sump. And all within 20 metres of buildings in this urban setting.

The Herrenknect machine, manufactured at the company’s facility in China, and reported to have cost $55 million to build and transport here, has been a star of the show at the project, which will complete the Western Ring Route when it is opened to traffic in a year’s time.

Designed and built specifically for Waterview, and with a cutting head measuring over 14 metres, it is the 10th largest ever used in the world. During its journey beneath Auckland, the earth pressure balance TBM placed 24,040 tunnel lining segments (10 to each of the 2404 rings) and excavated 800,000 cubic metres of spoil. It is believed to be the first TBM to be manufactured with an independent self-propelled culvert gantry. Designed to operate some 200 metres behind the TBM, the arrangement represents a departure from typical practice.

Precast steel fibre reinforced concrete segments measuring two metres by 450mm thick were supplied to the project by a sub-alliance with Wilson Tunnelling from a fabrication facility at East Tamaki. Each ring set featured nine segments, plus a crown key. In addition there were some 2400 inverted U-shaped precast concrete culverts, measuring two metres long by 3.7 metres wide by 2.2 metres high, cast to run under the road deck. Stefan Hanke, Alliance construction director says it was a ‘neat solution’ to keeping up productivity.

After the massive tunnels were bored and formed, SCC started the carefully planned, five-month job of dismantling the 87 metre long, 3400 tonne tunnel boring machine into its major components.

“Waterview has been a hugely significant project for Smith Crane and Construction, and has really put us on the map,” says Jason.

SCC’s presence on the site has spanned three years. The firm’s work included assembling and craning Alice into position, and turning her around once the first tunnel was complete so she could start boring the second tunnel, separated by a 15 metre gap.

“We have been working on and off on this project since March 2013, with up to 10 cranes and 30 staff involved at any one time. It is our biggest project to date in terms of value.”

The first stage of the process was to lift Alice’s rotating cutter head out of the Southern Approach Trench sump using a 600-tonne crane, with the assistance of a 300-tonne crane. The remainder of Alice’s parts including a shield, main drive, screw conveyor and tail skin followed. The parts are due to be shipped back to Herrenknecht.

Biggest in New Zealand

Recently a familiar sight on the Auckland skyline, the Liebherr LR1280 and Demag CC2800 worked together to remove the cutting head from the TBM.

“They’re the biggest cranes in New Zealand,” Jason told Contractor. In addition to the main drive (400-tonne) and cutting head (350-tonne) lifts, SCC has been involved in smaller day-to-day lifts on the project.

Understandably, dismantling Alice has called for considerable planning.

“For the bigger lifts, we’d prepared some 50-60 method statements, to be absolutely sure everything went exactly according to plan,” says Jason.

Even the logistics of getting the bigger cranes to the site required major planning. Establishing the Demag at the site required 43 loads to be transported by road.

“There was 550-tonnes of counterweight alone, in addition to boom and other components,” he adds.

The tunnel team recently completed the excavation of the last of the 16 cross passages that connect the twin three-lane motorway tunnels.

The cross passages are some 11 metres long and will be used to evacuate people if there is an emergency underground, and to house equipment to operate the tunnels.

Although excavation is complete there are still many months of work ahead – constructing the road surface, installing concrete linings, lights, drains, the deluge safety system and signage as well as painting the ceilings and walls – before the tunnels can be commissioned for the planned opening in early 2017.

“Dismantling Alice has taken a lot of work and planning,” says the Transport Agency’s highway manager, Brett Gliddon.

“The same ingenuity and accuracy that is the hallmark of the Waterview Connection is being used to remove the machine.

“It’s a very tight fit to get some of these pieces out, sometimes there’s been as little as 200mm to spare.”

The giant 322 tonne cutterhead that carved through underground spoil to drill the tunnels has now been lifted out of the trench. Six hydraulic jacks were used to push the cutterhead off the 184 studs that held it in place on the main drive of the TBM.

“Lots of people have asked us whether we can use Alice for other tunnelling projects, but each TBM is built specifically for one job. It’s designed to take into account the size of the tunnel and the type of material it’s boring through, which are individual for each project,”

says Gliddon.

The Waterview Connection completes Auckland’s Western Ring Route, a 48 kilometre alternative route to SH1. It will link Manukau, Auckland, Waitakere and the North Shore, improving network resilience, travel time reliability and bus shoulder lanes as well as upgrading cycleway and pedestrian facilities. It includes construction of twin three-lane tunnels – the longest road tunnels in the country – and a giant interchange to connect Auckland’s Northwestern and Southwestern Motorways (State Highways 16 and 20).

Who’s who at Waterview

The Waterview Connection project is being delivered by the Well-Connected Alliance which includes the Transport Agency, Fletcher Construction, McConnell Dowell, Parsons Brinckerhoff, Beca Infrastructure, Tonkin & Taylor and Japanese construction company Obayashi Corporation. Sub-alliance partners are Auckland-based Wilson Tunnelling and Spanish tunnel controls specialists SICE.

“To have completed so much tunnelling successfully and by the end of the year (2015) and without any major issues is a credit to the Well-Connected Alliance’s tunnel team,” says NZTA’s Brett Gliddon.

Tunnel construction manager, Chris Ashton says it has been a real team effort.

“It is a great achievement from everyone that there has been no discernible settlement or effect on people living above the tunnels. These cross passages have been built to world class standards with a very good safety record as well.”

Parting words from Jeremy Sole- a final column