In the years immediately following WWII there was an explosion of sorts in the development of the track type tractor, with several well established companies vying for the title of biggest, best and most powerful.

ALLIS-CHALMERS WAS THE FIRST to offer a really big track-type tractor in the form of its HD19. Things didn’t stay that way for too long however, as International Harvester launched its very popular TD24 in 1947 which quickly assumed the role of “biggest, best and most powerful”.

Allis-Chalmers then countered with its HD20 and so on it went until Caterpillar brought out the D9 in 1955.

The D9 was quite unlike anything that had been introduced before and was a real metal monster. The only machine that came close to it was the Euclid TC-12 but that had two engines for power whereas the D9 only had one.

The D9 had been in development since the mid-40s but Caterpillar was not satisfied with the various prototypes and kept on improving the design until it were sure the D9 was ready for public consumption.

The introduction of the D9 gave Allis-Chalmers and International-Harvester quite a shock – Allis-Chalmers never actually caught up until 1968 – and International, which was basking in the success of its TD24, went into panic mode.

Long time rivals, International-Harvester was always trying to gain an advantage over Caterpillar so the urgent request was made to the design team to develop a tractor that could take on the D9.

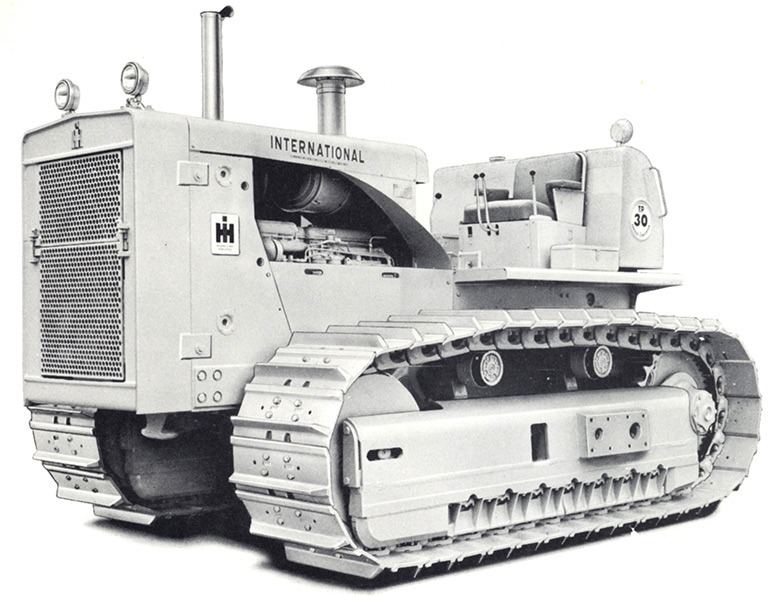

The result was the TD30.

Initial studies were based on modifications to its newest model (and TD24 replacement), the TD25.

The first TD30 prototypes went into testing during 1959 but the results were disappointing as many of the existing TD25’s components were not designed for the extra power or weight of the new tractor. Also by this time, Caterpillar had brought out its first D9 upgrade, the D9E, putting International even further behind.

Following more hasty design changes and upgrades, the TD30 was rushed into production, arriving with much fanfare in 1962.

Unfortunately for International, the end results of all this haste were more than predictable with TD30s failing all over the place.

The chief area of concern was the machine’s drive train, with transmission and final drive failures aplenty and many, many dissatisfied customers.

The TD30 had made an impact as intended, but for all the wrong reasons.

Despite attempts by IH engineers to rectify the TD30’s problems, the machine had been put into production well before it was ready and with inadequate testing.

The writing was on the wall for the big tractor with production of the direct drive model ending in 1965 and the slightly more reliable powershift version in 1967.

Total production of the TD30 amounted to only 683 machines.

International did go on to make a successful big crawler however in the form of the International/Dresser TD40 introduced in 1985.

The TD30 described

Based on the chassis of the existing TD25-250 series but weighing a whopping five tons more, the TD30 was powered by an in-line 6-cylinder International DT-817C turbocharged, after-cooled diesel rated at 320 flywheel horsepower. This was also the same engine used in the TD25 but with an increased rack setting.

Customers had their choice of transmissions, either a direct drive, 4-speed synchromesh with oil clutch and 2-speed planetary powershift steering in each track or a full 2-speed powershift type with a high and low range, effectively giving the machine 4 forward and reverse speeds.

The main chassis was comprised of two sections – a substantial one-piece welded and machined rear case, which contained the transmission, clutch (if fitted) and final drives, and a parallel box section front frame which held the machine’s engine and crosswise mount for the track equaliser bar. The front frame was bolted to the rear main case.

Featuring some fairly hefty track frames, the TD30 had seven track rollers and two carrier rollers per side and was usually delivered on 26” extreme service track shoes. Track gauge was 84 inches.

The operator’s deck was wide and reasonably unobstructed apart from the steering levers which projected out from under the seat.

It featured a tapered engine hood for good visibility to the blade. Instrumentation was grouped in a panel at the end of the hood.

A deeply cushioned seat was provided for the operator and this was often in silver or white, International’s answer to keeping the operator cooler!

Attachments & options

International designed a completely new set of work tools for the TD30 and did not adapt existing hardware to outfit the tractor for duty.

Customers had the choice of cable or hydraulically operated blades and the usual combination of one of these tractors was normally a 16 foot semi-U bulldozer with tilt cylinder and an Ateco radial arc ripper on the back. Full-U and angle blades could also be fitted.

As a number of these machines went into service as push tractors, International manufactured a most unusual cushioned push blade operated by a single hydraulic lift cylinder and featuring a cushion cylinder either side of the radiator cowl. It is not known how many of this particular version was produced but we have included a photo of one of these strange beasts for you to marvel over!

Carco manufactured a logging winch for TD30s that went to work in the woods.

Creature comforts included a cab, heater, wipers and ‘winterization kit’ for those tractors working in less than hospitable environments.

The New Zealand connection

At least three TD30s were imported by International Harvester New Zealand, initially all into the South Island. The last time the author saw one in action was in 1975 in Wellington on the Police Training College site that was a major Ministry of Works development at the time. It spent most of its time there with its cab off being attended to by mechanics.

Given the machines’ poor reliability record, it is unlikely that any survive but I would like to be proved wrong.

For the diecast model collector

Regrettably another non-starter, there are no models – past or present – of the International TD30.

Perhaps some enterprising soul will offer one some day as, apart from the machine’s rather dodgy reliability record, it would be nice to pose one in a representative lineup of 1960s bulldozers.