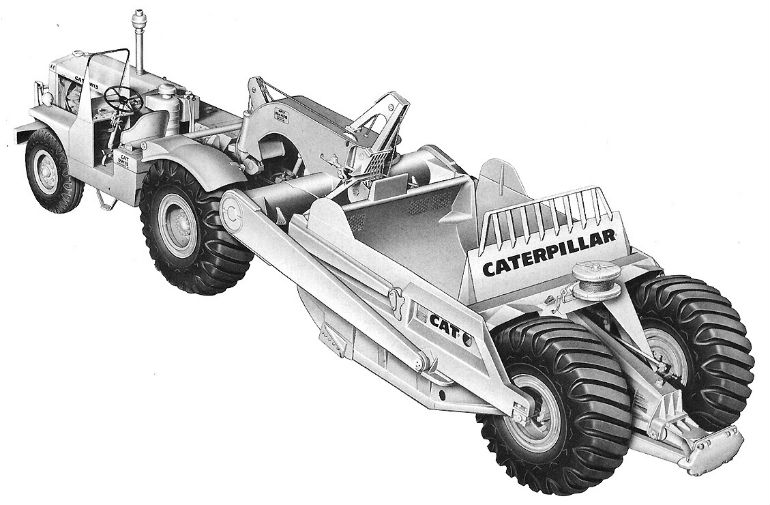

Developed from its DW10, Caterpillar’s first motor scraper, the DW15 featured several improvements over the former model. By Richard Campbell

The initial production model was the DW15C (45C series) introduced in 1955 and powered by a six-cylinder Caterpillar D326 diesel rated at 150 flywheel horsepower. This was mated to a Caterpillar 10-speed constant mesh transmission.

Purchasers had the option of Caterpillar’s No.10 or the newly designed No.15 scraper – the No.10 was rated at seven cubic yards struck and the No.15 had a capacity of 12.5 cubic yards – both were all-cable controlled by a Caterpillar No.27 double drum PCU.

Operating weight of the DW15C with No.15 scraper was 19 tons.

The DW15 was a basic “no-frills” get-the-job-done motor scraper which featured little in the way of operator comforts apart from a sprung suspension seat and a windshield. All controls were within easy reach and vision to the cutting edge was pretty good, for the time.

Easily read gauges (including an RPM counter with a tell tale) were placed in front of the operator on a well-equipped panel.

An air boosted clutch eased the transmission changes. In top gear, on a good haul road, the DW15 could reach a top speed of 37mph (faster downhill !)

Being a 3-axle machine the DW15 had fairly stable riding habits but could be easily jackknifed on a wet haul road.

Starting the machine was usually via the ubiquitous two-cylinder petrol engine although a direct electric starting option was available.

The new “lowbowl” family

Bearing a very strong resemblance to the previous DW10, the DW15C was in production for a relatively short period until it was replaced by the DW15E in 1957.

This was the most widely produced version of the machine and had an increase in horsepower from 150 fwhp to 186 flywheel horsepower.

It also featured a new cable controlled scraper, the No.428, rated at 13 cubic yards struck and 18 cubic yards heaped.

The No.428 was from the new “lowbowl” family of scrapers and was roughly equivalent to the towed No.435.

Both the No.15 and the No.428 scraper had fairly easy loading characteristics.

The DW15E remained in production for a little over two years and was replaced in 1959 by the final variant, the DW15F.

This differed very little from the previous E version other than in minor details such as a further horsepower increase (to 200) and styling changes.

By now the operating weight had increased to 20½ tons.

The DW15F was also the least prolific of the DW15 models. This was probably because, by 1959, most contractors preferred the flexibility and maneuverability of the small two-axle scraper such as Euclid’s S-7 and Le Tourneau Westinghouse’s D Tournapull. Both of these could be roaded from job to job without a permit and turn within their own length, tasks not within the DW15’s capability.

By 1961 the DW15 had been replaced in Caterpillar’s catalogue by the 619 – a considerably bigger machine than its predecessor.

Caterpillar never offered a small open bowl scraper again until the model 611 was introduced in the 1990s.

A range of attachments was manufactured by Athey, Hyster and Rome for Caterpillar Tractor Co to extend the usefulness of the DW15 tractor.

These included a rock dumper, side dumper, flat deck trailer and lowboy (Athey), compactor wheels (Hyster) and segmented compactor wheels (Rome).

As an interesting aside, surviving DW15’s are considered collectors items among tractor enthusiasts in the USA.

The New Zealand Connection.

New Zealand Caterpillar dealer Gough Gough and Hamer imported approximately 16 machines during the 1950’s.

They found homes in Whangarei (McBreen-Jenkins), Nelson (Roadways Ltd) and others but the largest customer was W.Stevenson of Auckland.

Used on all sorts of jobs, the DW15’s appear to have been well liked by those who owned and operated them.

As is often the case with older machines, a use was found for the DW15 after its economic scraping days were over. This was usually as a prime mover for towed compactors although more than one New Zealand machine has been converted to a self-propelled compactor, the rear wheels being replaced by wedgefoot compaction drums.

Many of the No,15 and No.428 scrapers have been converted into tractor-towed units, their cable controls replaced by hydraulics.

Brief Specifications (DW15E)

Engine: Caterpillar D326F, 6-cylinder, naturally aspirated. 186hp @ 2000rpm.

Transmission: Caterpillar 5-speed manual gearbox with splitter giving 10 forward speeds and two reverse.

Clutch: 16” double plate dry, with air booster.

Brakes: Air operated, expanding shoe.

Steering: Worm & ball with hydraulic booster.

Tires: Tractor front – 12.00 x 20.

Tractor drive – 26.5 x 25.

Scraper – 26.5 x 25.

Capacity: Struck – 13 cubic yards

Heaped – 18 cubic yards.

Control: All cable via Caterpillar No.27 double drum PCU.

O/all Length: 40’ 1”

Height: 10’

Width: 10’ 10”

Op.Weight: 44,711lb (19.9 tons) empty, 83,711 (37.3 tons) loaded.